The water is then taken care of with ultraviolet (UV) gentle or ozone to destroy any remaining microorganisms. The water is then saved in sterile containers and is examined regularly to make sure that it fulfills the expectations set through the USP and BP.

It may be saved for intervals as much as a month in Unique tanks made up of ultraviolet lamps. When this freshly geared up water is stored and sterilized in hermitically sealed containers, it'll remain in very good problem indefinitely.

Pumps should be of sanitary style and design with seals that prevent contamination on the water. Valves should have clean inner surfaces with the seat and shutting system subjected to the flushing motion of water, for instance happens in diaphragm valves. Valves with pocket areas or closing devices (e.g., ball, plug, gate, globe) that transfer into and out from the movement place must be avoided.

A different prevalent type of filtration program used inside the pharmaceutical industry is ultrafiltration. These devices are typically used when filter pores are required to be 0.01 micron in measurement. Ultrafiltration not simply eliminates little particles within the flow of material, In addition, it eliminates some viruses or other microorganisms that may be existing during the stream, for instance bacteria and protozoa.

The chemical characteristics detailed in these monographs needs to be considered as a list of least requirements. A lot more stringent technical specs can be necessary for a few programs to ensure suitability for distinct utilizes. Standard assistance on the right applications of these waters is located in the monographs and is also additional stated On this chapter.

When it comes to selecting a filter type, There are a selection of various things that should be regarded. With Those people used inside the pharmaceutical industry, There are some different filters to select from.

RO units is usually used alone or in combination with DI and CEDI models and ultrafiltration for operational and quality enhancements.

Sterile water for irrigation is frequently packaged in containers that are generally better than 1 L in dimension.

Techniques generating WFI also ought to undertake a validation process to be sure it's manufacturing water that fulfills the expected specifications in an effort to be used properly.

Auxiliary equipment and fittings that call for seals, gaskets, diaphragms, filter media, and membranes should exclude supplies that allow the possibility of extractables, shedding, and microbial action. Insulating components exposed to chrome steel surfaces must be free of chlorides to avoid the phenomenon of pressure corrosion cracking that may result in technique contamination along with the destruction of tanks and significant program components.

Thinking of the likely problem for objectionable microorganisms elevated by this sort of superior microbial amounts from the feedwater, informing the municipality of the trouble so they may start corrective steps ought to be a right away first step. In-house remedial actions may or may not also be desired, but could consist of carrying out added coliform screening within the incoming water and pretreating the water with possibly supplemental chlorination or UV light irradiation website or filtration or a combination of strategies.

It is necessary to note that the quantity of columns inside a MED design would not decide the ultimate good quality in the output. A better variety of columns simply translate to reduce resource consumption.

Packaged waters present a particular dilemma relative on the attributes of conductivity and TOC. The deal alone is definitely the source of chemical compounds (inorganics and organics) that leach over time in the water and can easily be detected. The irony of organic and natural leaching from plastic packaging is the fact that if the Oxidizable substances exam was the sole “natural and organic contaminant” exam for each bulk and packaged waters, that check's insensitivity to Those people natural leachables rendered their presence in packaged water at large concentrations (many times the TOC specification for bulk water) virtually undetectable.

Water that does not fulfill the criteria for Safe and sound drinking is known as non-potable water, but its quality should allow it to be useful more info for other explanations.

Mara Wilson Then & Now!

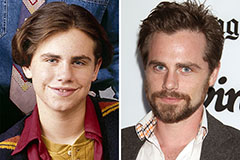

Mara Wilson Then & Now! Rider Strong Then & Now!

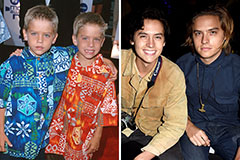

Rider Strong Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Romeo Miller Then & Now!

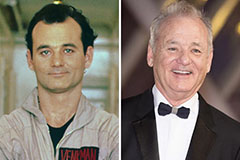

Romeo Miller Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now!